Author: Editorial board

Tailor-made solutions to support the needs of the clients

Customisation has become an asset in today’s market. Customers not only want functional products, but also look for solutions that incorporate new aesthetic requirements in line with the final requirements.

This assumption applies to the various application sectors we serve: from household appliances, to heating, ventilation and air-conditioning(HVAC) equipment to commercial applications in the HoReCa sector.

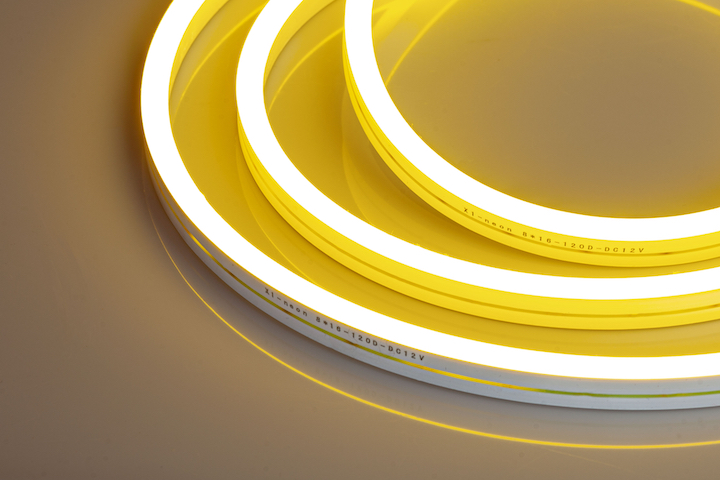

One solution for customising these products is the integration of custom light indicators. Thanks to the technologies available today, custom light indicators can be created in a wide range of colours and shapes, and can be programmed to suit the customer’s specific needs. With these solutions, companies can improve the appearance of their products and offer their customers a unique and personalised experience.

Find out more in this article about SLIM’s tailor-made lighting solutions.

Click on the button below to find out more about our company!

SLIM’s custom lighting solutions

Whether it is a light indicator for the oven or washing machine, a spotlight for the coffee machine or a light profile for professional equipment, customisation of a product, for us at SLIM, takes place at different levels.

On the one hand, customisation begins from standard products to catalogue, in this case, the customer can request the sampling of an existing product with certain modifications: it is possible to intervene at the level of light source or components (lens, colour, request for cables with particular technical specifications, IP grade, etc.).

Parallel to standard customised products, at SLIM we develop full-fledged custom products that tend to be based on the customer’s specific request.

Custom lighting solutions are realised from the development of a printed circuit placed inside them. The plastic case where the PCB will be placed is developed based on the overall dimensions and technical specifications provided by the customer: it houses an LED or several LEDs depending on the quality, quantity and type of light desired. What are the fundamental steps that lead to custom solutions? Let’s take a look together.

Research and innovation

Research and innovation in the development of tailor-made solutions are two crucial aspects based on a series of creative and technological processes.

The main steps that can be followed during a project start-up stage are indicated below:

- Market analysis: the first step in researching and innovating customised lighting solutions is market analysis. This involves understanding market needs and trends, assessing competitors and identifying opportunities for innovation.

- Materials research: once innovation opportunities have been identified, the search for materials used to develop new customised solutions can begin. This may include the use of new materials or the combination of existing materials in an innovative way.

- Development of new technologies: in some cases, research and innovation of customised lighting solutions may require the development of new technologies. This was the path that led us to the development of the micro LED spotlights and the optical fibre with light source. For more information click here and download the document on SLIM’s tailor-made solutions in cooperation with several customers.

Design and prototyping

The design and prototyping of customised lighting solutions can be complex processes: the use and implementation of advanced tools and technologies guarantee efficiency and a high level of quality.

Below are the main steps in the design and prototyping process of custom lighting solutions:

- Customer needs analysis: the first step in designing customised solutions is to analyse the customer’s needs. This includes understanding the required technical specifications, desired functionality, aesthetic requirements and available budget.

- Conceptual design: once the customer’s needs are understood, SLIM’s technical department can start developing design ideas and solutions. At this stage, it is important to consider factors such as the shape, size (overall dimensions), colour, brightness and durability of the custom lighting solution.

- 3D model: after selecting the appropriate concept design , the designer can use 3D modelling software to create a virtual model of the custom lighting solution. This model can be used to test functionality, evaluate appearance and make modifications.

- Prototyping: once the 3D model has been approved by the customer, the designer can move on to the prototyping stage. This may include the creation of a physical prototype, using additive manufacturing techniques such as 3D printing.

- Testing and evaluation: after creating the physical prototype, the customised lighting solution must be tested to assess its functionality, reliability, durability and overall quality. Depending on the test results, further modifications can be made to improve the custom lighting solution.

- Production: lastly, once the prototype has been tested and approved, it will move on to the production phase. This may include the production of pilot batches for further testing and evaluation before moving on to mass production.

Are you looking for a customised lighting solution? Click on the button below and put us to the test with a challenging request for state-of-the-art light signalling!