Germicidal UV-C LED: what it is and how it works

Over the last year, the interest in sanitisation devices has increased significantly as a direct consequence of the Covid-19 emergency. The sanitisation of rooms and surfaces, as well as the purification of air and water have, now more than ever, become synonyms of health and safety. This has led to an increase in UV and UV-C technology which, through the use of UV light succeeds in inactivating viruses and bacteria.

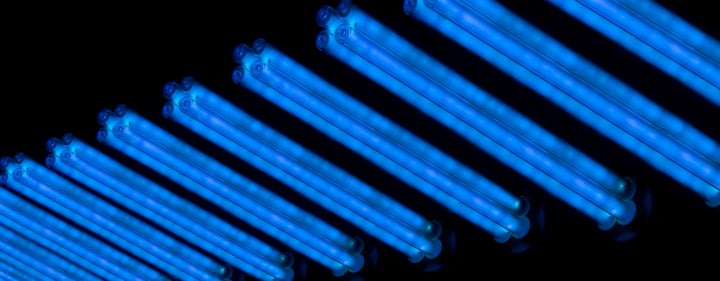

Lighting devices with UV ultraviolet ray emission technology are among the most commonly requested solutions both in the form of mercury vapour germicidal lamps and as UV-C LED lighting and UV-C LED light strips for their ability to destroy organic and inorganic molecules, viruses and bacteria, without the use of toxic chemicals.

Which is the best germicide device? In this article, we shed light on the topic to understand how to choose reliable, high-quality technology.

In particular, we will talk about:

- UV-C LED lighting: what it is

- UV-C LED lamp and UV-C LED light strips: the differences

- UV-C LED steriliser: how it works

- UV-C LED lighting in Italy

- SLIM and UV-C LED lighting: products and applications

Would you like to stay constantly updated on the latest news in the sector? Click on the button below and subscribe to our newsletter!

UV-C LED lighting: what it is

The UV-C lamp is a specific type of lamp that produces ultraviolet light which can sanitise rooms.

Mercury vapour lamps used to be used to generate UV-C rays, an effective technology for removing microorganisms, but with a limited life span of the source and highly polluting due to the presence of mercury.

UV technology combined with LED technology, with a wavelength of around 265nm and 280nm, has led to the development of UV-C LED lamps, an innovative and above all safe, sustainable and economical device.

Compared to traditional UV lamps, germicidal UV-C LED technology has smaller and more compact dimensions and is thus more versatile and adaptable to different types of applications.

In addition to offering a better performance in terms of pollution and size, UV-C LED lamps also have other benefits in terms of:

- emission: the emission of the LED light is concentrated in a single direction with a light angle ranging from 30° to 120°, this results in a perfectly collimated emission beam, so that it is directed at a precise target without dispersion;

- energy saving: LED technology is renowned for low consumption and here again, energy saving is an advantage compared to the choice of a mercury lamp;

- duration: LED lights have a longer average lifetime compared to the hours of life of a mercury UV lamp;

- on/off cycles: unlike mercury vapour lamps, LED lamps light up immediately without the need for “heating”, providing the maximum amount of germicidal efficacy and with the possibility of carrying out an almost unlimited number of on and off sequences, without negatively impacting the emission features;

- portability: LED lights can be easily integrated into compact technology without a power cable, but only simple batteries, so that the device can be easily moved;

- control: LED lights can be easily controlled, adjusted and guided remotely on demand.

UV-C LED lamp and UV-C LED light strips: the differences

The basic element of UV-C LED technology is the UV-C LED light which comes in the most standardised format, i.e. a UV-C chip integrated into a transparent resin casing from which metal pins emerge, or in the SMD format.

A UV-C LED manufacturer can supply UV-C LEDs individually, laying them out on strips wound on coils for assembly on a PCB through pick & place, or ready-assembled on adhesive strips available in different formats. A germicidal UV-C LED application can, therefore, be achieved as required, either by using single LEDs assembled on a PCB, or by using a UV-C LED light strip consisting of UV-C LEDs ready-assembled on a support, which can then be cut to the most suitable size for your application.

If you choose to use the germicidal UV-C LED light supplied individually in coils, it is necessary to design and produce the PCB on which the LED will be assembled, identifying not only the most suitable type of LED but also all the electronic components required for its correct operation. Another important aspect is the development of the heat dissipation system, if LEDs, with high powers that heat up quickly, are used and the design, therefore, of a suitable housing.

The use of a UV-C LED strip, on the other hand, does not require the design of a dedicated PCB. The downside is, however, that the LED strip only allows you to lay out the LEDs in a straight line, so you need to figure out how to dissipate the heat through the use of metal profiles, to which the germicidal UV-C LED strip will be applied. Choosing this format also results in a lower final cost of the product compared to the solution using one or more LED lights mounted on a PCB.

Despite some differences, choosing one solution over the other does not make any difference in terms of germicidal efficacy, as the bactericidal effect depends on the type of LED used, not on the format itself, on the wavelength ans emitted distance and time.

UV-C LED steriliser: how it works

Germicidal radiation through ultraviolet rays is an effective method for sanitising, disinfecting the air and sterilising material surfaces.

How does a UV-LED lamp work? Germicidal UV radiation is a sterilisation method that uses UV light at a UV-C wavelength, but first a distinction needs to be made about the wavelength of the rays. UV sources can be divided according to the wavelength of the ultraviolet ray in the solar spectrum. On the basis of this parameter, the UV modules are used in different sectors and applications:

- UV-A: long wavelength from 315nm to 400 nm, the UV-A modules are used for medical and industrial use;

- UV-B: medium wavelength from 280nm to 315 nm, the modules are used mostly for medical treatments;

- UV-C: short wavelength from 200nm to 280 nm.

Given that the UV-C modules have a short wavelength, they are more aggressive than the UV-A modules and, therefore, more effective for disinfecting areas quickly. The most effect germicidal wavelength occurs between 250 and 275 nanometres, so the 265 nm UV-C LED lamp is one of the best solutions for rapid surface sanitisation. In this case, the short wavelength of the UV-C LED sterilisers can destroy the DNA or RNA of bacteria and viruses, preventing them from performing several vital cellular functions. This allows for water, air and surfaces to be fully sterilised.

UV-C LED lighting in Italy

UV-C LED modules are devices with a wide variety of applications. In Italy, UV-C LED lighting is used for many purposes in various applications sectors to:

- purify air and water;

- preserve fruit and vegetables in the fridge;

- sanitise food production lines;

- reduce the microbial load;

- eliminate unpleasant odours;

- improving living conditions in closed spaces.

Whatever reason you decide to use UV-C LED technology for your application, remember that direct exposure to UV-C LED light is quite dangerous; the rays can cause health risks if used incorrectly. Therefore, the presence of special systems in the facility is recommended to avoid causing harm to humans. These include the possibility of using timers or operating time controls, “absence” detectors or smart sensors to manage the facility, to ensure that the 254nm UV-C LED lamps are not used in the presence of a person.

Click on the button below and discover the last SLIM case study about the collaboration with Quick Mill and the LED UV-C sterilizer.

SLIM and UV-C LED lighting: products and applications

SLIM has combined its knowledge in the field of LED light signalling with the demand for sanitisation by creating specific UV-C LED devices which can be adapted to the customer's end applications. Among the UV-C LED suppliers, the UV-C LED products supplied by SLIM are used in water and air purification devices (UV-C LED air disinfection) and in the sanitising devices that are part of food production lines. We have opted to use the SMD format for our applications because it offers a much wider range of products from which to choose.

From the sanitisation of coffee machine tanks to cleaning and ventilation systems, SLIM is at your disposal thanks to the creation of custom germicidal UV-C LED lights, ready for installation on the final application.

Are you interested in finding out more about this topic to develop a possible application with a UV-C LED solution? Click on the button below, our technical staff is always available to assess any specific requirement with you.